How we install injection filters for ISCO, ENNA, and other injection projects

3 March 2025

How we install injection filters for ISCO, ENNA, and other injection projects

On this webpage, we describe how we install our injection filters used for In-situ Chemical Oxidation (ISCO), ENNA, and other injection jobs where we inject liquids into the soil. Proper sealing is crucial to prevent leakage along the filter. This webpage is intended for clients and (drilling) subcontractors.

Procedure

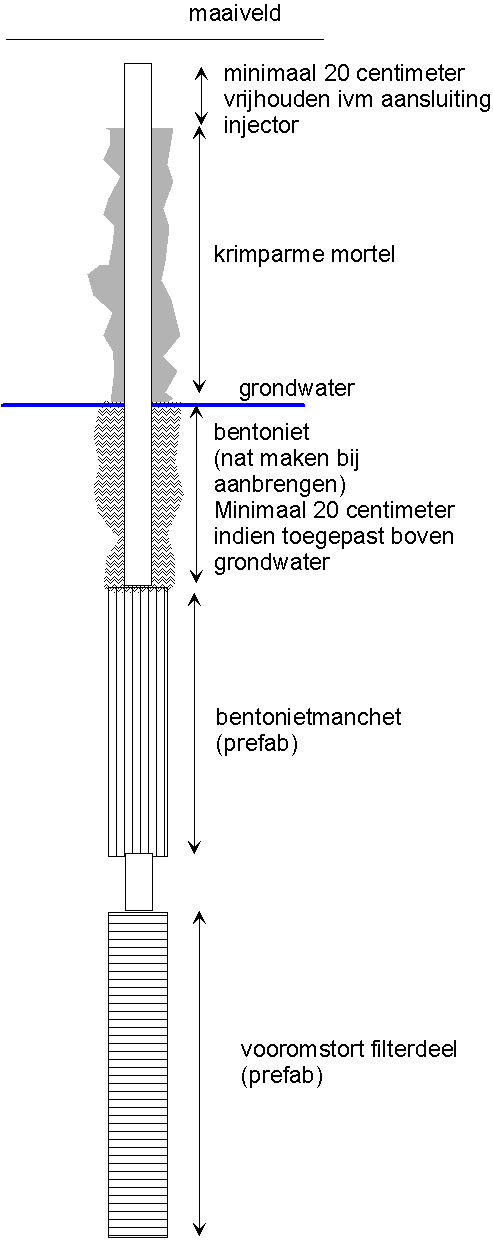

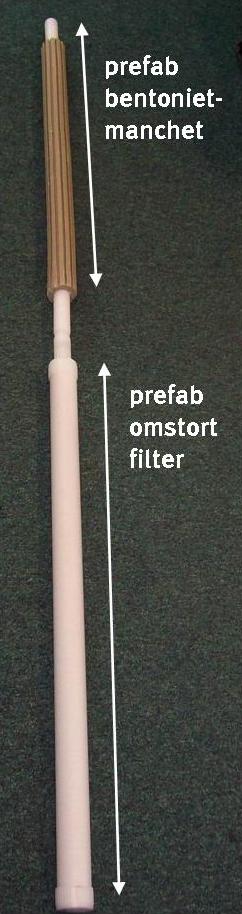

HMVT uses so-called quality filters (PE 32 mm) as injection filters. This filter features pre-applied gravel packing. Above that, a prefabricated bentonite sleeve is applied. The filter is then backfilled with bentonite up to the groundwater level. When applied above the groundwater level, at least twenty extra centimeters of bentonite is added above the prefabricated bentonite sleeve. The bentonite is well-watered to ensure proper expansion. Once the bentonite has fully swollen (minimum of 4 hours), the remaining borehole around the filter is filled with shrink-resistant (wet) concrete mortar. The top twenty centimeters of the filter are left free to allow proper connection of the injector head later. A resting period of at least one week is then observed to allow the filter to harden properly.

This method results in a high-quality injection filter. The filter's centered prefabricated backfill provides excellent permeability. The combination of the prefabricated bentonite sleeve, additional bentonite, and concrete backfill ensures an exceptionally pressure-resistant seal around the blind riser pipe, preventing leakage to the surface and other more permeable intermediate layers.